Industrial ovens are an essential piece of equipment for a wide range of manufacturing industries. They are used to heat-treat, dry, cure, and bake various materials, such as metals, plastics, ceramics, composites, and food substances. In this article, we will delve into the world of industrial oven manufacturing, exploring the different types of ovens available and the manufacturing process itself.

Types of Industrial Ovens

Industrial ovens come in many different shapes and sizes, each designed to suit a specific application. Some of the most common types of industrial ovens include:

- Batch Ovens: These ovens are designed for small to medium-sized batches of products. They are typically used for curing, drying, and baking.

- Conveyor Ovens: These ovens are designed for large-scale manufacturing processes where products need to be processed continuously. They feature a conveyor belt that moves the product through the oven.

- Tunnel Ovens: These ovens are similar to conveyor ovens, but the products move through a tunnel instead of on a conveyor belt.

- Cabinet Ovens: These ovens are designed for small-scale production processes or laboratory use. They are ideal for applications that require precise temperature control.

Manufacturing Process

The manufacturing process for industrial ovens is complex and requires a high level of expertise. Here are the key steps involved in the process:

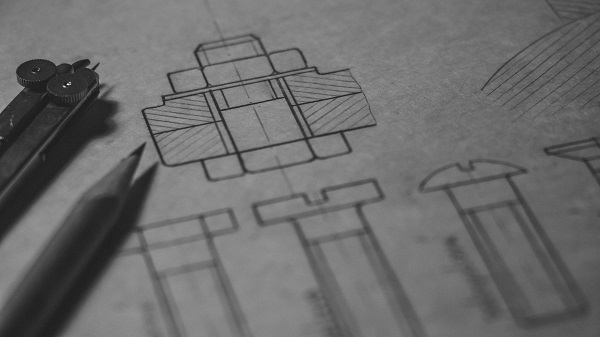

Design: The design process starts with an understanding of the customer’s requirements. This involves a detailed analysis of the product to be manufactured and the specific process requirements. Once the requirements are understood, the oven is designed using computer-aided design (CAD) software.

Fabrication: The fabrication process involves cutting and shaping the oven’s metal components. This is done using a variety of tools, including saws, drills, and welding equipment.

Assembly: The next step is to assemble the oven’s components. This involves fitting the metal panels together and attaching the electrical and heating components.

Testing: Once the oven is assembled, it undergoes a series of tests to ensure that it meets the customer’s requirements. This includes temperature testing, airflow testing, and safety testing.

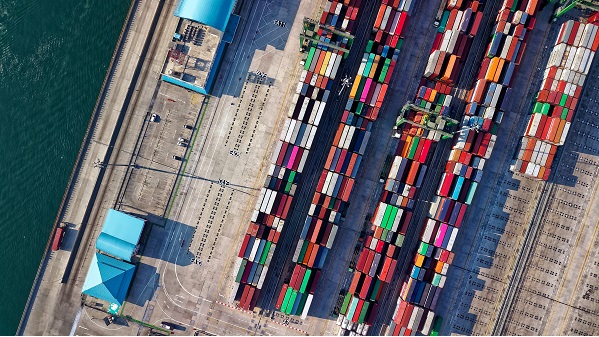

Shipping: Finally, the oven is shipped to the customer’s location. This is done using specialized equipment to ensure that the oven is transported safely.

Quality Control

Quality control is a crucial aspect of industrial oven manufacturing. This involves a range of checks and tests to ensure that the oven meets the customer’s requirements and is safe to use. Some of the key quality control checks include:

- Welding Inspection: The welding on the oven is inspected to ensure that it is of high quality and free from defects.

- Electrical Inspection: The electrical components of the oven are tested to ensure that they are functioning correctly and are safe to use.

- Temperature Testing: The oven is tested at various temperatures to ensure that it can maintain a consistent temperature throughout the heating cycle.

- Safety Testing: The oven undergoes a series of safety tests to ensure that it is safe to operate and that all safety features are working correctly.

Industrial ovens are essential pieces of equipment for a wide range of manufacturing industries. They are designed to heat-treat, dry, cure, and bake various materials, such as metals, plastics, ceramics, composites, and food substances. The manufacturing process for industrial ovens is complex and requires a high level of expertise. Quality control is a crucial aspect of industrial oven manufacturing to ensure that the oven meets the customer’s requirements and is safe to use. If you are in the market for an industrial oven, it is important to work with a manufacturer that has a proven track record of quality and reliability.

Many businesses have relied on East Key Industrial for helping them find the right manufacturing solution for their industrial oven projects, resulting in successful commissioning of oven lines. Get in touch if you need a free quotation or advice on your Industrial oven line.